How 3D Printing Is Revolutionizing Mesh Design

Compartir

3D printing has transformed a number of industries, and mesh design is no exception. This innovative technology not only allows for the creation of more complex and customized designs, but also streamlines manufacturing processes, reduces production time, and minimizes material waste. In this article, we will explore how 3D printing is significantly impacting mesh design and the advantages it offers for businesses and consumers.

The Age of Personalization

One of the biggest benefits of 3D printing is the ability to effectively customize products. In the context of mesh design, this means that designers can create meshes that perfectly fit each customer’s individual specifications.

Custom Designs

Thanks to 3D printing, we are no longer limited to standard design meshes. Designers can use 3D modeling software to create unique meshes that meet specific user needs. This includes:

- Ergonomic shapes that better adapt to the human body.

- Custom colors and textures to suit style preferences.

- Specific adaptations for functional or sporting particularities.

The ability to customize tights is a huge draw for designers and consumers alike, as it results in products that are more comfortable and align with the customer’s brand identity.

Materials Optimization

The use of 3D printing in mesh design has also allowed companies to optimize the use of materials. Traditionally, the mesh manufacturing process can result in a high level of waste, but with 3D printing, complex structures can be created that use only the necessary amount of material.

Reducing Waste

When a mesh is 3D printed, the material is deposited layer by layer, creating only what is needed. This technique not only results in the reduction of waste, but also helps to lower costs related to production. Companies that implement this technology can take advantage of it to:

- Increase sustainability in your production processes.

- Reduce costs by minimizing the use of materials.

- Generate lighter products without compromising strength.

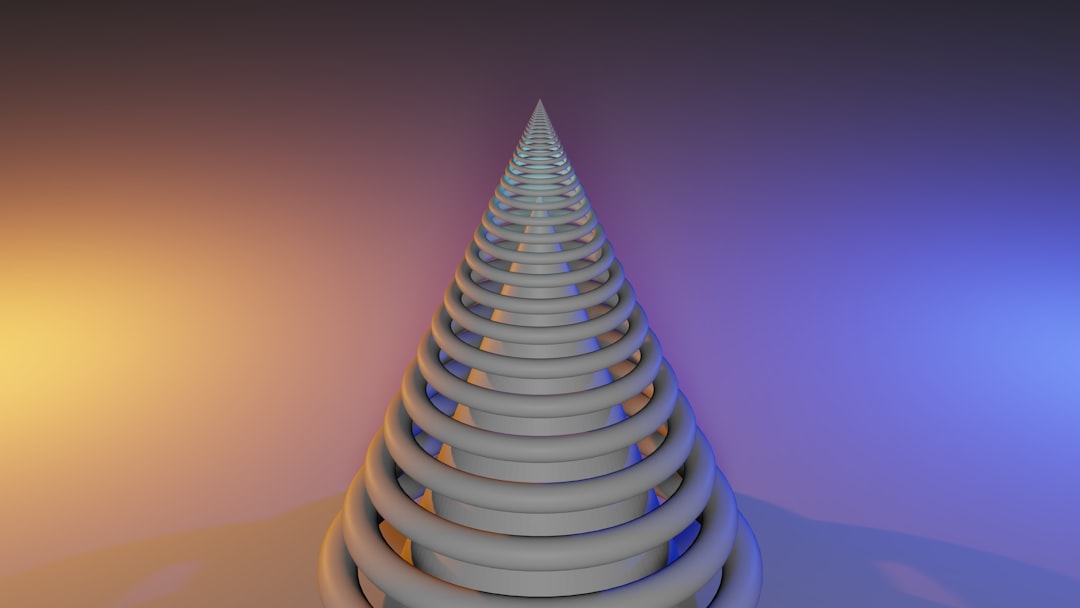

Innovation in Design

3D printing has also pushed the boundaries of design in the creation of meshes. Designers have the freedom to experiment with complex structures and patterns that were previously impossible to achieve using traditional manufacturing methods.

Complex Structures

3D printing allows for the creation of meshes with intricate geometries, which translates into features such as:

- Increased breathability thanks to innovative design patterns.

- Optimized structural stress improves durability.

- Aesthetically appealing visual designs that capture attention.

These innovations not only improve the functionality of mesh, but also open up new possibilities for designers looking to differentiate their products in a competitive marketplace.

Fast and Efficient Production

Speed of production is another area where 3D printing shines in mesh design. Traditional manufacturing techniques often require long production and processing times, whereas 3D printing can carry out these processes in a much shorter time.

From Idea to Reality

The process of taking a mesh design from idea to reality can be extremely fast thanks to 3D printing. This involves:

- Rapid prototyping that allows for real-time design evaluation and modification.

- On-demand production eliminates the need to maintain large inventories.

- Ability to continuously adapt to market trends.

Cost Reduction

Many business owners who venture into 3D printing for mesh design are surprised to find that they can significantly reduce production costs. This is achieved through the integration of new technologies into their workflows, which creates efficiencies in several areas.

Lower Initial Investment

Unlike traditional production, which often requires large investments in specific machinery and tools, 3D printing allows companies to get started with a lower initial investment. The accessibility of 3D printers and associated software makes this technology more accessible to small and medium-sized businesses.

Scalable Economies

As a company grows, 3D printing allows it to scale its production quickly without the need for large investments in infrastructure. This allows for sustainable and calculated growth in the mesh design market.

The Future of Mesh Design

3D printing in mesh design is just beginning to show its potential. As technology advances, we can expect to see even more innovations and improvements in this field.

Advanced Materials

With the development of new materials, such as biocompatible or recycled plastics, the future of mesh design looks promising. These materials not only improve product quality, but also contribute to more sustainable production.

Technology Integration

Incorporating sensors and wearable technology into the design of tights is another exciting area to explore. Imagine tights that automatically adjust to body temperature or measure physical performance. 3D printing can make this a reality.

The Social and Environmental Impact

Finally, there is the social and environmental impact that 3D printing is having on the mesh design industry to consider. Thanks to the sustainability and efficiency that this technology offers, significant steps are being taken towards a more responsible and conscious future.

Local Production

One of the emerging trends is local production through 3D printing. Not only does this support local economies, but it also reduces the carbon footprint by minimising the transportation of goods. Companies can produce mesh on-site and according to consumer demand, which benefits everyone involved.

Become Part of the Revolution

3D printing is revolutionizing the way we conceive and design meshes. From customization and material optimization, to design innovation and rapid production, the opportunities are endless. If you are a designer or business owner, now is the time to take advantage of this exciting technology and adapt your design and production strategies.

Don’t be left behind in this revolution. Start exploring how 3D printing can improve your business and offer your customers a unique, high-quality product that really stands out. The era of custom, sustainable tights is here, and you can be a part of it!

Explore the Shopify store of a user by clicking here . Keep in mind that this is a promotional link, and we are not responsible for the content on the linked store.